Support

Please use our Support page to find out more information on our

products and to help you find the right solution.

-

HOW TO Programme the RCU1 Remote & Switch

In this video we will show you how easy it is to pair a RCU1 control unit to a remote transmitter (RCU1-RC1) and wireless switch (RCU1-SWITCH).

-

HOW TO Programme the WCC 103BT Remote and App

In this video we will show you how easy it is to pair the WCC 103BT and WCC 106BT control unit with a remote transmitter. We will also show you how to pair the unit to an app on your smart device.

-

HOW TO Programme the EVC Control Unit & Remote

In this video we will show you how easy it is to pair a EVC control unit to an EVC weather station and EVC-RC8 remote transmitter.

-

HOW TO Programme the S50-DC Remote

In this video we will show you how easy it is to pair a S50-DC control unit to a S50-DC-RC remote transmitter.

-

HOW TO Programme the CCU2

In this video we will show you how easy it is to programme a CCU2 control unit.

-

HOW TO Programme a CCU3 Remote & Switch

In this video we will show you how easy it is to pair a CCU3 control unit to a RCU3-RC1 remote transmitter and RCU3-SWITCH wireless switch.

Frequently Asked Questions

Need a little extra information? Take a look below and see if we have the answer.

-

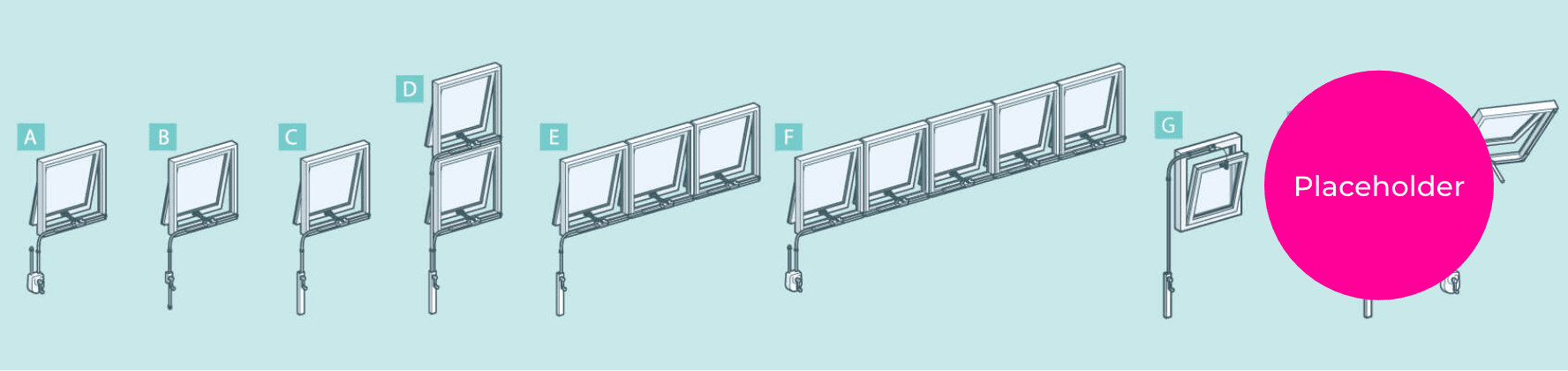

If fitting a single chain actuator to a top-hung or bottom-hung window we recommend a maximum window width of 1300mm. For anything wider we recommend multiple synchronised chain actuators.

Still need help?

-

Our Italian friends at Mingardi SRL have a useful formula for calculating such things.

Calculation for top-hung windows:

F = (C ÷ H) x (P ÷ 2)

F = Required force (kg)

P = Weight of the window (kg)

C = Opening stroke (mm)

H = Height of the window

Calculation for bottom-hung windows:

F = (C ÷ H) x (P ÷ 2)

F = Required force (kg)

P = Weight of the window (kg)

C = Opening stroke (mm)

H = Height of the window

Calculation for roof vents:

F = (P + Cn) ÷ 2

F = Required force (kg)

P = Weight of the roof vent (kg)

Cn = Snow load

Code Push Force Link MICRO EVO1 300N MICRO EVO2 400N MICRO 02 150N WMX 804 200N WMX 814 150N WMX 826 200N WMU 836 300N WMU 842 400N WMU 851 500N WMU 861 600N WMU 862 600N WMU 882 1000N L25 250N L35 350N D8 FCE 500N EURO 1 450N S08 650N WMS 306-N 600N WMS 309-N 900N WMS 409-N 900N DRIVE EVO2 550N WMD 820 200N FTA600DF 600N FTA600GF 600N FTA600R 600N Still need help? Contact our technical team who will be happy to help!

-

If an actuator or set of actuators need to be controlled from a BMS we recommend a control interface is used to ensure the correct operation of the actuator(s). These can be supplied with BACnet or KNX cards allowing actuator position feedback to the BMS. For this type of application we would recommend one of the following control unit’s are used:

Code BACnet Compatible KNX Compatible Modbus Compatible Link WCC 310 PLUS Yes Yes – Product page WCC 320 PLUS Yes Yes – Product page SCP500 – – Yes Product page SCP800 – – Yes Product page WSC 310 PLUS Yes Yes – Product page WSC 320 PLUS Yes Yes – Product page WSC 520 Yes Yes – Product page WSC 540 Yes Yes – Product page WSC 560 Yes Yes – Product page -

All of our actuators have a range of fixing brackets available. The best suited will depend on the hinge type, frame type and fixing space available.

-

Check the connections at the control unit and junction box local to the actuator to ensure it has been wired as per the installation instructions. In most cases the open and close signal wires need swapping over.

-

No. Retro fitting an actuator to a window for smoke venting purposes would not constitute an EN12101-2 smoke vent and therefore would not comply with CPR 2013 regulation. CPR 2013 requires any life safety products (in this case the Smoke Vent / AOV) to be CE Marked and this is only possible if there is a fully audited production process for the AOV, and a declaration of performance can be made by the manufacturer. To achieve compliance we recommend one of our fully compliant EN12101-2 smoke vents.

-

Most of our actuators are available in black, silver or white finish as standard. If you need a specific RAL colour or need to match the window profile we offer a wet spray service for the actuator and bracket set.

-

The opening stroke sizes for our actuators range from 50-1200mm. The best suited will depend on the window size, hinge type, weight, frame type and application.

-

This will depend on the actuator current consumption (A) and control unit maximum motor load (A). You must not exceed the maximum motor load on the control unit. See below:

Code Maximum Motor Load Motor Output Link CCU1 8A 230V CCU2 8A 230V CCU3 6.3A 230V EVC 4A 230V PSU-2 2A 24V PSU-4 4A 24V PSU-8 8A 24V RCU1-KIT 3.15A 230V S50-DC 3A 24V WCC 103 3A 24V WCC 103BT 3A 24V WCC 106BT 6A 24V WCC 310 10A 24V WCC 320 20A 24V WCC 310 PLUS 10A 24V WCC 320 PLUS 20A 24V SCP500 5A 24V SCP800 8A 24V WSC 204 4.8A 24V WSC 310 PLUS 10A 24V WSC 320 PLUS 20A 24V WSC 520 20A 24V WSC 540 40A 24V WSC 560 60A 24V VCS-S2 5A 24V Actuators

Code Current Consumption Voltage Link MICRO EVO1 230V MICRO EVO1 1A 24V MICRO EVO2 230V MICRO EVO2 1A 24V MICRO 02 230V MICRO 02 24V WMX 804 1A 24V WMX 814 1A 24V WMX 826 1A 24V WMU 836 1A 24V WMU 842 2A 24V WMU 851 1A 24V WMU 861 1A 24V WMU 862 2A 24V WMU 882 2A 24V L25 230V L35 230V D8 FCE 230V EURO 1 230V EURO 1 24V S08 24V WMS 306-N 24V WMS 309-N 24V WMS 409-N 24V DRIVE EVO2 24V WMD 820 1A 24V FTA600DF 24V FTA600GF 24V FTA600R 24V -

Yes. Most of our control units have this feature as standard but some will need an additional module to facilitate a fire alarm signal input.

Code Fire Alarm Input Link SCP500 Built in SCP800 Built in WSC 204 Additional WSA 306 module required WSC 310 Built in WSC 320 Built in WSC 310 PLUS Built in WSC 320 PLUS Built in WSC 520 Built in WSC 540 Built in WSC 560 Built in VCS-S2 Built in -

This will depend on the actuator current consumption (A), control unit maximum motor load (A) and size of cable. Our actuators are available in 230V or 24V and you must ensure the voltage drop is no greater or less than 10%.

-

There are several fault indicators for each control unit. To determine the fault type and the fix for that fault please download the relevant installation instructions which will include this information.

-

A smoke ventilation control unit/AOV panel/smoke vent panel is used to control single or multiple smoke vents within a building. Subject to the design and fire strategy in place a smoke ventilation control unit can be triggered manually using a manual call point or automatically from a smoke sensor, fire alarm system or BMS. Depending on the command the smoke ventilation control unit will power the connected smoke vent(s) open or closed.

A smoke ventilation control unit also has built-in battery backup meaning in the event of a mains power failure the system can continue to operate on batteries for up to 72 hours.

Teal Products stock a large range of AOV smoke panels including:

Code Motor Output Motor Load Motor Lines Link SCP500 24V 5A 1 SCP800 24V 8A 1 WSC 204 24V 4.8A 1 WSC 310 24V 10A 2 WSC 320 24V 20A 2 WSC 310 PLUS 24V 10A 2-10 WSC 320 PLUS 24V 20A 1-10 WSC 520 24V 20A 1-13 WSC 540 24V 40A 1-26 WSC 560 24V 60A 1-39 VCS-S2 24V 5A 1 The most suitable will depend on the application and fire strategy in place.

-

The cable type and size will depend on the input or output you are connecting to the control unit. Please refer to the installation instructions for details.

-

AOV stands for Automatic Opening Vent. An AOV or multiple AOV’s will form part of a smoke ventilation system typically achieving a 1m2 or 1.5m2 free area in accordance to the designed fire strategy.

Code Type Application Link SV-R-RL1 AOV Roof Hatch SV-R-RL3 AOV Roof Hatch SV-R-L2 AOV Roof Louvre SV-R-L3 AOV Roof Louvre SV-R-CP2 AOV Centre Pivot Window SV-W-L2 AOV Façade Louvre SV-W-GL1 AOV Façade Glazed Louvre SV-W-GL2 AOV Façade Glazed Louvre SV-W-W1 AOV Façade Window SV-W-W2 AOV Façade Window SV-W-D3 AOV Shaft Damper SV-W-D4 AOV Shaft Damper -

Yes. Our range of AOV roof and façade smoke vents are certified and tested to the current EN 12101-2 product standards. Our AOV smoke shaft vents are certified and tested to the current EN 12101-8 product standards.

-

This will depend on the location of the smoke vent within the building and the fire strategy in place.

Typically within a stair core the minimum requirement is for the AOV smoke vent to have a minimum free area of 1m2. This could be in the form of an AOV roof vent or AOV façade vent such as:

Code Type Link SV-R-RL1 AOV Roof Hatch SV-R-RL3 AOV Roof Hatch SV-R-L2 AOV Roof Louvre SV-R-L3 AOV Roof Louvre SV-R-CP2 AOV Centre Pivot Window SV-W-GL1 AOV Façade Glazed Louvre SV-W-GL2 AOV Façade Glazed Louvre SV-W-W1 AOV Façade Window SV-W-W2 AOV Façade Window A head of shaft AOV typically is asked to achieve a minimum free area of 1m2. This would be in the form of an AOV roof vent such as:

Code Type Link SV-R-RL1 AOV Roof Hatch SV-R-RL3 AOV Roof Hatch SV-R-L2 AOV Roof Louvre SV-R-L3 AOV Roof Louvre A smoke vent opening into a smoke shaft for natural smoke ventilation will need to achieve a minimum free area of 1m2. This would be in the form of an AOV shaft vent such as:

Code Type Link SV-W-D3 AOV Shaft Damper SV-W-D4 AOV Shaft Damper A smoke vent located in a lobby or corridor will need to achieve a minimum free area of 1.5m2. This would be in the form of an AOV façade vent such as:

Code Type Link SV-W-GL1 AOV Façade Glazed Louvre SV-W-GL2 AOV Façade Glazed Louvre SV-W-W1 AOV Façade Window SV-W-W2 AOV Façade Window

-

If fitting a single chain opener to a top-hung or bottom-hung window we recommend a maximum window width of 1000mm. For anything wider we recommend multiple chain openers.

-

The T100 and T150 chain openers have a range of fixing brackets available. The best suited will depend on the hinge type, frame type and fixing space available. Speak to our team to find the best solution for your window.

-

AOV stands for Automatic Opening Vent. An AOV or multiple AOV’s will form part of a smoke ventilation system typically achieving a 1m2 or 1.5m2 free area in accordance to the designed fire strategy. Teal Products supply a large range of AOV products including:

Code Type Application Link SV-R-RL1 AOV Roof Hatch SV-R-RL3 AOV Roof Hatch SV-R-L2 AOV Roof Louvre SV-R-L3 AOV Roof Louvre SV-R-CP2 AOV Centre Pivot Window SV-W-L2 AOV Façade Louvre SV-W-GL1 AOV Façade Glazed Louvre SV-W-GL2 AOV Façade Glazed Louvre SV-W-W1 AOV Façade Window SV-W-W2 AOV Façade Window SV-W-D3 AOV Shaft Damper SV-W-D4 AOV Shaft Damper -

Yes we do! We offer a large range of training courses including:

- Smoke ventilation building regulations

- Smoke ventilation product standards

- Smoke ventilation commissioning

- Smoke ventilation product training

-

This will depend on the location of the smoke vent within the building and the fire strategy in place.

Typically within a stair core the minimum requirement is for the AOV smoke vent to have a minimum free area of 1m2. This could be in the form of an AOV roof vent or AOV façade vent such as:

Code Type Link SV-R-RL1 AOV Roof Hatch SV-R-RL3 AOV Roof Hatch SV-R-L2 AOV Roof Louvre SV-R-L3 AOV Roof Louvre SV-R-CP2 AOV Centre Pivot Window SV-W-GL1 AOV Façade Glazed Louvre SV-W-GL2 AOV Façade Glazed Louvre SV-W-W1 AOV Façade Window SV-W-W2 AOV Façade Window A head of shaft AOV typically is asked to achieve a minimum free area of 1m2. This would be in the form of an AOV roof vent such as:

Code Type Link SV-R-RL1 AOV Roof Hatch SV-R-RL3 AOV Roof Hatch SV-R-L2 AOV Roof Louvre SV-R-L3 AOV Roof Louvre A smoke vent opening into a smoke shaft for natural smoke ventilation will need to achieve a minimum free area of 1m2. This would be in the form of an AOV shaft vent such as:

Code Type Link SV-W-D3 AOV Shaft Damper SV-W-D4 AOV Shaft Damper A smoke vent located in a lobby or corridor will need to achieve a minimum free area of 1.5m2. This would be in the form of an AOV façade vent such as:

Code Type Link SV-W-GL1 AOV Façade Glazed Louvre SV-W-GL2 AOV Façade Glazed Louvre SV-W-W1 AOV Façade Window SV-W-W2 AOV Façade Window